Posted by Electric Solenoid Valves on Oct 28th 2025

What Is a Y-Strainer and How Does It Work?

A Y-strainer (a.k.a. wye strainer) is a compact inline filter that catches debris—rust flakes, pipe scale, sand, Teflon tape fragments—before it reaches sensitive components like solenoid valves, pumps, meters, and spray nozzles. Fluid enters the body, flows through a removable stainless screen in the Y-branch, and exits cleaner on the downstream side. Debris stays in the pocket so you can purge or remove it without pulling the whole strainer from the line.

Why add a Y-strainer?

- Protects precision parts: Solenoid valve seats and pilot passages are tiny; grit can jam them open/closed or cause weeping. A Y-strainer removes the bulk of contaminants first.

- Improves uptime: Fewer nuisance failures, fewer callbacks, more predictable actuation.

- Cuts maintenance cost: Cleaning or flushing a screen takes minutes compared to replacing a fouled valve.

- Stabilizes your process: Cleaner media = more consistent flow, pressure, and spray/nozzle performance.

How a Y-strainer works (step-by-step)

- Flow entersthe strainer body and is directed into the screen element in the angled branch.

- Particles larger than the openings are trapped on the upstream side of the screen.

- Cleaned fluid exits downstream to your valve, pump, or instrument.

- Maintenance options: Either open the cap to remove/rinse the screen, or add a blow-out (blow-down) kit so you can crack a small valve and flush debris without disassembly.

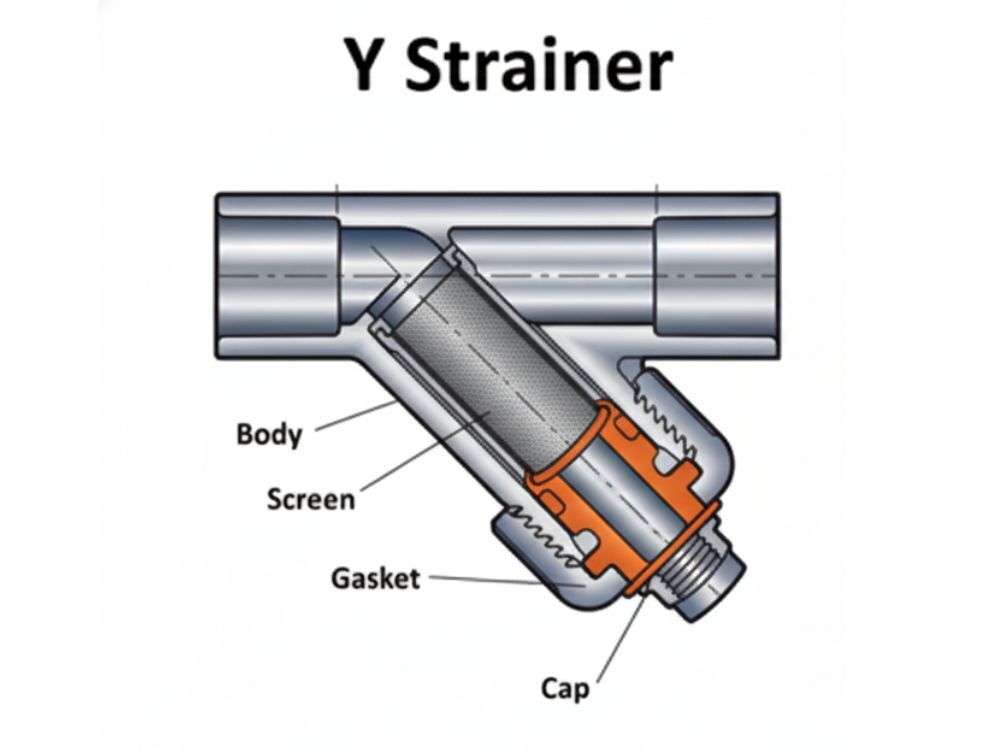

What’s inside (and why it matters)

- Body: Compact stainless construction sized for common NPT lines; durable and easy to seal in typical water/air service.

- Screen: Cylindrical stainless mesh/perf that sets your filtration level. Swaps in seconds.

- Cap & port: The end cap seals the screen chamber and often includes a threaded drain/blow-down port—perfect for adding a purge valve.

- Gasket/seal: Chosen to hold pressure and temperature; replace if nicked to prevent weeps. (Keep a couple of spares with your extra screens.)

Mesh & Micron

Electronicsolenoidvalves’ Y-Strainers ship with an 80-mesh stainless screen by default. Replacement screens are available in 50, 80, and 150 mesh, corresponding to approximate openings of 297 µm, 177 µm, and 89 µm. That lets you tune filtration to the smallest sensitive orifice downstream without over-restricting flow.

- 50 mesh (~297 µm): Coarser option with maximum debris capacity and longer intervals between cleans—good when water is sandy, pipes shed scale, or downstream orifices aren’t ultra-small.

- 80 mesh (~177 µm): A strong general-purpose choice for many water/air lines feeding solenoid valves and ball valves; balances protection and maintenance.

- 150 mesh (~89 µm): Fine filtration for tiny orifices, pilot passages, and precision nozzles. Expect more frequent cleaning or plan to add a blow-down for quick purges.

Practical starting point: Install the included 80-mesh. If you’re cleaning too often, step coarser to 50; if fines still reach a tiny orifice, step finer to 150 and schedule shorter intervals.

Y-strainer vs. other strainer types

- Y-strainer: This is a versatile option for small to medium-sized lines. It's compact, can be mounted horizontally or vertically, and is easy to purge and clean.

- Basket strainer: These have a larger screen area, making them suitable for high-flow applications, but they are bulkier and typically designed for horizontal lines.

- Inline screens/mini filters: These are excellent for use as a "last-chance" filter near an instrument, but they have limited capacity for holding dirt.

Sizing for flow, viscosity, and pressure drop

Every strainer adds some resistance. Your goals: protect equipment without starving it and keep ΔP manageable as the screen loads.

- Match pipe size in most cases; upsize the strainer only if viscosity is high or you anticipate a heavy debris load.

- Estimate clean-screen ΔP using Cv/K-factor data when available; then watch how ΔP rises in your real-world conditions.

- Consider viscosity: Water-like fluids tolerate finer mesh; thicker glycols/oils may need coarser mesh or a larger body for more screen area.

- Design for maintenance: If your process is sensitive to pressure, add a blow-out kit so you can purge collected debris between full cleanings.

Installation best practices

- Orientation: In horizontal runs, point the screen pocket down so gravity collects debris in the chamber. In vertical down-flow, ensure that the branch is still on the low side.

- Follow the arrow: Install in the tested flow direction indicated on the body; even on bidirectional designs, use the orientation that keeps the pocket low.

- Add isolation: Put ball valves or unions upstream and downstream so you can service the screen without draining long stretches of pipe.

- Use compatible sealants: Apply thread sealant sparingly so you don’t shed paste/tape into the fresh screen.

- Commissioning check: New piping almost always sheds debris—plan an early inspection.

Maintenance & cleaning (quick, reliable workflow)

- Isolate and depressurize the section.

- Fast purge (optional): If you’ve installed a Blow-Out (Blow-Down) Kit, crack the purge valve briefly to flush the debris pocket without disassembly—great for holding ΔP down between deep cleans.

- Full clean: Remove the cap slowly, pull the screen, and rinse from the clean side out so you don’t push particles deeper into the weave.

- Inspect the screen: Look for tears or any collapse/deformation (a sign of water hammer or excessive differential). Replace if damaged.

- Re-gasket, reseal, leak-check.

- Set your interval: Log time/ΔP rise between cleanings. Dirtier sources (well water, older steel pipe, certain process loops) need more frequent checks. ESV’s guides repeatedly emphasize correct mesh selection and regular cleaning as the key to long service life.

Pairing Y-strainers with solenoid valves

Solenoid valves, especially pilot-operated designs with small pilot passages, are sensitive to debris. Symptoms of poor filtration include sticking open/closed, buzzing or chattering, and tiny seat leaks. Installing a Y-strainer upstream protects the pilot and main orifices, reduces nuisance failures, and keeps actuation behavior consistent—even when your supply carries fine particulate.

For small-orifice or zero-differential/direct-acting valves, start with 80-mesh and move to 150-mesh only if required by the orifice size, noting that maintenance frequency will increase. These valves are more sensitive to clogging due to low actuation force, which justifies finer mesh selection.

Common applications

- Water systems: Irrigation, well water, cooling loops, spray bars, misting lines

- Compressed air: Rust scale and pipe debris that can jam actuators and instrument valves

- Heat-transfer/glycol loops: Protects exchangers and control valves (confirm compatibility)

- Process/industrial: Meters, regulators, dosing nozzles, and steam lines when materials/ratings allow

- High-purity environments: Keeps particulates out of sanitary runs when paired with appropriate materials/gaskets (e.g., EPDM, PTFE)

Selection checklist (copy/paste this when you buy)

- Media & chemistry: Choose stainless body and screen materials compatible with your fluid and cleaners.

- Pipe size & connection: NPT sizes from ½″–2″ cover most small/medium lines; match pipe unless you need more screen area.

- Mesh/micron: Start at 80-mesh (included); step to 50 for longer intervals with gritty water or 150 for tiny orifices/nozzles.

- Pressure & temperature: Verify ratings vs. worst-case conditions.

- Service plan: Ensure wrench clearance for the cap, keep spare screens and gaskets on hand, and consider a blow-out kit.

- Pressure drop: Estimate clean ΔP and watch how quickly it rises in your real system.

Practical Takeaways

A Y-strainer is low-cost, high-impact protection for clean, reliable flow. By catching rust, scale, and tape fragments before they reach small orifices and pilot passages, you prevent nuisance failures, stabilize pressure/flow, and extend the life of solenoid valves, pumps, and instruments. Start with the included 80-mesh screen, then adjust to 50-mesh for gritty sources or 150-mesh for tiny downstream orifices. Install with the pocket low, isolate for service, and either add a blow-down port or plan short, regular cleanings. A few minutes of prevention here saves hours of troubleshooting later. Shop Electronicsolenoidvalves’ Y-strainers and screens, or contact us for quick sizing help.

FAQs

Are Y-strainers directional?

Follow the flow arrow on the body and orient the pocket down so gravity helps debris settle. This improves capture and makes purging more effective.

What mesh should I use to protect a solenoid valve?

ESV ships Y-strainers with 80-mesh (~177 µm) as a strong general-purpose baseline. If you’re cleaning constantly, go coarser (50-mesh); if you have very small orifices that still pass fines, go finer (150-mesh) and plan more frequent maintenance.

Will a Y-strainer reduce my flow a lot?

A clean screen adds modest pressure drop; ΔP rises as the screen loads. If your process is sensitive, either upsize the strainer for more screen area or add a blow-down to purge more often.

Can I purge without taking it apart?

Yes. Install ESV’s Blow-Out Kit on the cap’s drain port to flush trapped debris quickly and safely between full cleanings