Feb 1st 2023

NPT Threading Explained

Threaded fittings are an essential component in many fluid control systems, including solenoid valves and related products. One type of thread you might come across is the National Pipe Thread Taper (NPT) thread. In this blog post, we'll explain what NPT threads are, their benefits, and how they are used in solenoid valves and related products.

NPT threads are a type of tapered thread commonly used in piping systems throughout North America. The NPT thread has a unique design that helps ensure a tight seal and prevents leaks, making it a popular choice in many industries, such as plumbing, HVAC, and pharmaceutical manufacturing.

In the following sections, we'll take a closer look at NPT threads, how they are used in products like electric solenoid valves and related products, and the advantages they provide.

What Are NPT Thread Fittings?

NPT threads are a specific type of tapered thread commonly used in piping systems throughout North America. The term "National Pipe Taper" (NPT) refers to a specific type of tapered thread that connects pipes and fittings. They can be made of metal, like cast iron, steel, bronze, brass, or plastic, like nylon or PVC.

The NPT thread is a standard thread type and is defined by the American National Standard for Tapered Pipe Threads (ANSI/ASME B1.20.1). This standard specifies the size, angle, and depth of the thread and ensures that NPT threads are consistent in size and form, which helps to ensure reliable and leak-free connections.

Why are NPT and NPTF pipe threads tapered?

The tapered design of NPT and NPTF (National Pipe Thread Fuel) threads creates a tighter seal as the fitting is threaded deeper into the pipe. This is an important feature when dealing with liquid and gas flowing systems since it helps to prevent leaks. This design is particularly important in fluid transfer parts of systems where leaks can be dangerous or costly.

The taper on NPT and NPTF threads creates a mechanical interlocking effect between the fitting and the pipe. As the fittings and pipe are screwed together, the threads compress slightly as they are threaded deeper into the pipe, creating a tighter seal.

NPT Male and Female Fittings

The fitting is considered male if the threads are on the outside. Male fitting threads may be called MPT, MNPT, or NPT(M). Threads on the inside indicate it is female. Female fitting threads may be called FPT, FNPT, or NPT(F). Both NPT (male) and NPTF (female) threads have the same pitch, 60-degree angle, and flat peaks and valleys shape.

If you’re wondering about the difference of MNPT vs NPT, MNPT is the specific NPT male thread. While in the case of NPT vs NPTF, NPTF is the specific female NPT fitting thread.

With tapered connections, the male fitting has a thread that locks into the female fitting and then expands until the amount of force between the two can withstand pressure from materials traveling through the pipes. Sealant is required on threads before assembly due to the small clearance between the crest and root of the connecting NPT threads.

The NPTF thread does not require sealant. Instead, it contacts and deforms the mating thread crest. Although lubricant is often used to help with sealing, the NPTF provides a dry thread seal by design.

NPT Thread Sizing and Tolerance

NPT threads are measured and sized according to a specific and standardized system (ANSI/ASME B1.20.1). Pitch diameter, major diameter, and minor diameter are used in the sizing of NPT threads. The tolerance requirements for NPT threads are critical for achieving optimal performance and reliability of threaded connections. Tolerance affects the tightness and stability of the connection, and precise tolerances are necessary to prevent leaks and other issues in fluid transfer systems.

Two Categories of ANSI/ASME Threading Standards

Within the commonly used classification of thread fittings, there are two specific types that some people may occasionally mix up: National Pipe Taper (NPT) and National Pipe Straight (NPS).

As mentioned above, NPT threading has a tapered design that helps form a connection that prevents leaks in fluid/gas systems. NPS threads (or sometimes called parallel) fittings, on the other hand, are straight threads that are typically used for quick connections that do not require a tight seal.

NPS threads are level and are mainly used for electrical and mechanical needs. However, proper sealing for NPS fittings also requires additional pieces, such as gaskets or o-rings.

You can determine whether your fitting is a straight or tapered thread by simply measuringthe first, fourth/fifth, and last threads. It is a tapered thread style if the diameter increases or decreases from one end to the other. If the diameter remains the same across, it is a straight thread.

The sharply angled tapered threads of an NPT fitting compress as the pipe screws into a joint, which creates a strong seal. Using a thread sealant with NPT style fittings is best to achieve a fully effective, leak-free seal. (The exception is NPTF fittings, which we'll discuss further down in this article.) In contrast, straight threads only hold the pieces together. NPS connections allow a nut to move freely up and down the connection, whereas NPT connections lock tightly once in place.

NPT and NPS thread fittings are not interchangeable as they will not seal together properly. Inherently, neither system is better than the other. Depending on the purpose, each thread works effectively.

Both threading type specifications are set and maintained by American National Standards Institute (ANSI)

- NPT falls under ANSI B1.20.1 Pipe Threads, General Purpose, Inch

- NPS falls under ANSI B1.20.3 Dryseal Pipe Threads, Inch

NPT vs. BSP

The other most common type of tapered threaded fittings used in fluid transfer systems is known as BSP (British Standard Pipe) threads. The United States and Canada use the NPT classification system, while the rest of the world mainly uses BSP.

Both standards specify the types of screw threads that fit and seal pipe fittings that are used for different purposes. Within their own classification system, some varieties of threads are compatible. Still, you cannot mix and match between the two classification systems due to the different pitches and thread forms.

One of the main differences between NPT and BSP threads is the pitch of the thread. NPT threads have a finer pitch, which means that the threads are closer together and there are more threads per inch.

Another characteristic to note is that the peaks and valleys differ. Peaks and valleys are flat with an NPT thread, while BSP peaks and valleys are rounded. In addition, NPT fittings will have threads with a 60-degree spread, and BSP threads will have a 55-degree spread. These differences make them incompatible. Therefore, it is necessary to correctly identify your connection to create a safe and leak-resistant seal.

If you do not know which type of fitting you have, you can use a pitch gauge to measure the spread of the threads. The video below shows how to use a screw pitch gauge for something like this.

Finding the Standard Trade Size Match

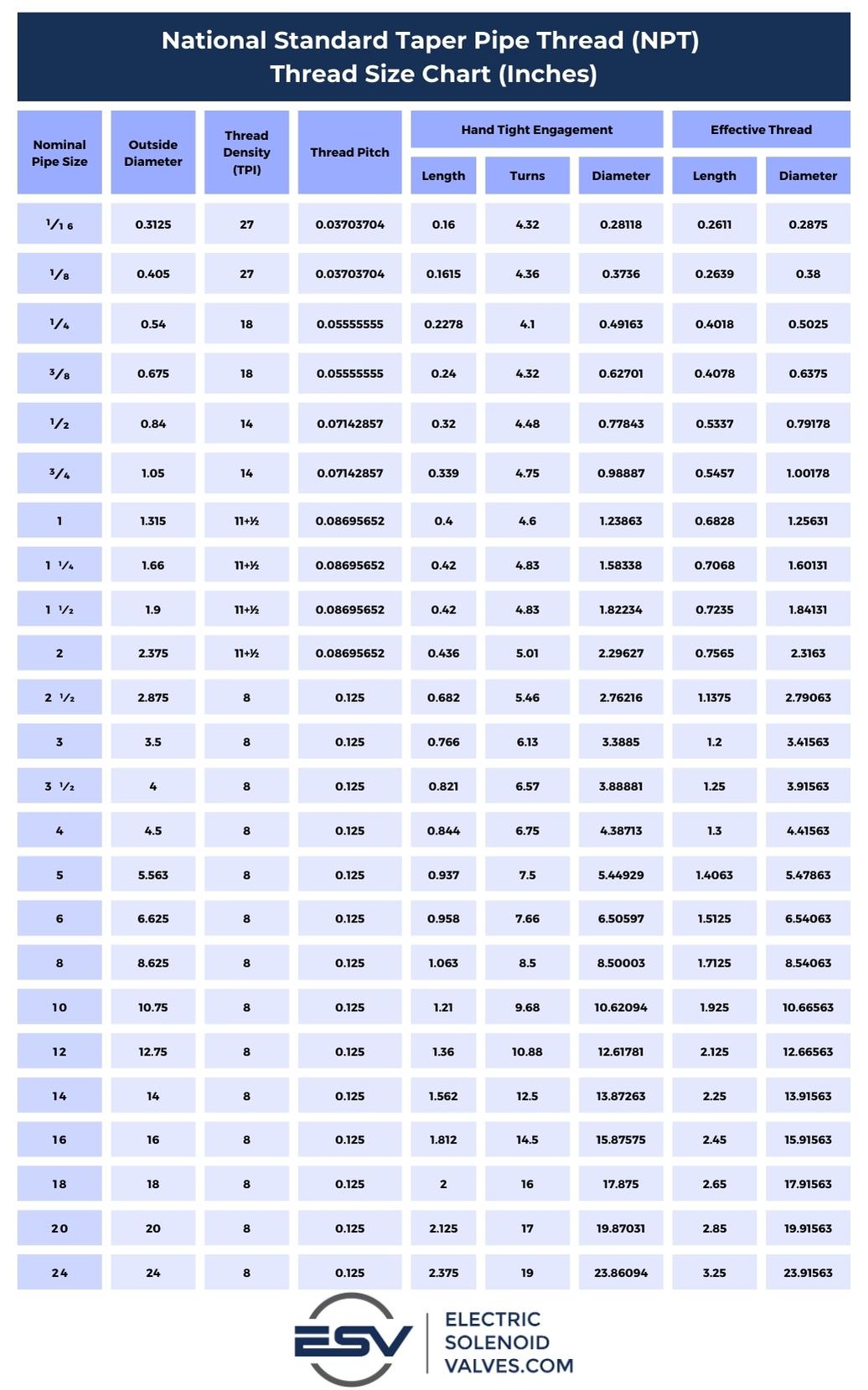

You will want to know what size thread fittings you are working with. To find the standard trade size, you must first know whether the thread is straight or tapered. Then you can measure the diameter of any thread on an NPS fitting, or if it is an NPT fitting, you will need to measure the fourth or fifth thread.

This measurement is then referenced in a thread table to match its trade size. Be aware that the trade size does not directly represent what is measured, i.e., ½ inch NPT does not equal ½ inch measured.

NPT is the most widely known and used fitting. The most common US supplier sizes are 1⁄8, 1⁄4, 3⁄8, 1⁄2, 3⁄4, 1, 11⁄4, 11⁄2, 2, 21⁄2, 3, 4, 5, and 6 inches. Fittings less than ⅛ inch are sometimes used with compressed air, while the larger sizes (over 2 inches) are less common, mainly because other joining methods are needed.

Advantages and Disadvantages of Using NPT Fittings

What Are the Advantages of Using NPT Fittings?

NPT threads are commonly used in industries such as oil and gas, chemical processing, water treatment, and many others where leak-free connections are of the utmost importance. The tight seal and stability provided by NPT threads make them well-suited for use in challenging environments, such as high-temperature, corrosive, and abrasive conditions. Additional benefits includes:

- An effective lubricated seal.

- Readily available with vendors.

- Easy to find in multiple sizes.

- Various materials are available (cast iron, bronze, steel, brass, PTFE, nylon, PVC).

- Easier to assemble without the use of sleeves, seals, or o-rings.

What Are the Disadvantages To Using NPT Fittings?

Though NPT threading is optimal for most fluid and gas systems, there are some negatives:

- Requires lubricant (except NPTF), which can cause system contamination.

- Not suitable for the highest pressures.

- Best used for single assembly as sealing performance can decrease with reassembly.

- Larger sizes are more prone to leaking due to leak path size.

- Prone to damage from over-tightening.

- Harder to orient shaped connectors.

Other Common American Thread Types

NPT and NPS are not the only types of American threading types. There are several others, including NPSF, NPSC, NPTR, NPTF, NPSH, NPSM, NPSI, and NPSL. Each of these threads has its own unique characteristics and is used in specific applications.

- NPSF: National Pipe Straight Fuel - for dry seal applications with soft materials.

- NPSC: American Standard Straight Coupling Pipe Thread - for general couplings.

- NPTR: American Standard Taper Railing Pipe Thread - for railings.

- NPTF: American Standard Pipe Thread Tapered (Dryseal) - for dry seal connections in nearly every type of service, especially fuel connections. A lubricant is often used to ease assembly.

- NPSH: National Pipe Straight Hose - for water suction pipes and discharge hose couplings.

- NPSM: American Standard Straight Mechanical Pipe Thread - for rigid mechanical uses.

- NPSI: National Pipe Straight Intermediate - for free-fitting mechanical joints for fixtures.

- NPSL: American Standard Straight Locknut Pipe Thread - for use with locknuts.

Other Common British Thread Types

BSP (British Standard Pipe) is the standard used in the commonwealth countries and Australia. BSP is based on trade size rather than actual diameter.

- BSPP: British Standard Pipe Thread Parallel - requires a bonded seal ring.

- BSPT: British Standard Pipe Thread Tapered - metal wedging creates the seal.

Both fittings in a BSPT connection do not have to be tapered, unlike NPT connections. For instance, you can use a female fitting that is tapered with a straight male fitting. However, all BSPT connections must use a thread sealant.

NPT/NPS style threads are similar to BSP, but as we mentioned above, there are differences in thread dimensions, pitch, and angle, which make them incompatible. Another important difference between BSP threads and NPT threads is that BSP threads are measured in metric units, while NPT threads are measured in imperial units.

In Conclusion

It is vital to know whether you are working with NPT or BSP standard thread fittings. With that information, you will want to consider your pipes' purpose to determine which specific thread type you need for your valves and other fittings. You can then move forward with finding the correct thread fittings: straight, tapered, male, or female.

Being clear on your NPT thread fitting will help to ensure you have the proper materials to achieve the results you're looking for.

Thank you for taking the time to learn about NPT threads and their variants. If you're in need of solenoid valves or automated ball valves with NPT threaded fittings for your fluid transfer system, electricsolenoidvalves.com has a wide selection to choose from, available with the shortest lead times. Our knowledgeable team is here to answer any questions you may have and help you find the best threaded fitting for your specific needs. Don't hesitate to reach out for assistance – we're here to help!