Dec 9th 2022

Comparing Direct vs Indirect vs Semidirect Valves

Solenoid valves are electromechanical devices used to control the flow of fluids. They are widely used in HVAC, oil & gas, and automotive industries to control or mix fluids.

A solenoid valve consists of a coil that creates a magnetic field when an electric current is passed through it. The magnetic field creates a force (electromagnetic force) on the plunger to close or open the valve, depending on the valve's resting position (Normally Open or Normally Closed).

Based on their working principle, solenoid valves can be classified into three main types: direct-acting, indirect-acting, and semi-direct. In this resource article, we will discuss these three popular types of solenoid valves and their advantages and disadvantages so that you can make an informed decision to select the right one for your needs.

Direct Action Solenoid Valves:

Direct-acting solenoid valves function by using a magnetic force to open and close an orifice, directly regulating the liquid flow. Because the maximum flow rate through a direct-acting valve is directly proportional to the orifice size, these valves are only used when small amounts of fluids need to be controlled. Due to their simpler working principle, these valves do not require a minimum pressure or pressure difference to function and hence can be used in applications from zero bar up to the valve’s maximum allowable operating pressure.

Advantages of Direct acting SVs:

- Operates irrespective of the pressure difference between ports

- Minimum moving parts, resulting in low maintenance and longer service life, and switching cycles

- Compact and cost-effective

- Does not rely on holes/diaphragms/passageways and are therefore debris resistant

Disadvantages of Direct acting SVs:

- Limited flow capabilities, best suited for low flow/discharge rates

- Higher power consumption compared to other valve types

- With a high-frequency power supply, the coil is susceptible to burn easily

Applications:

Direct acting SVs are often used for shut-off, dosing, filling, and ventilation applications. They are most suited for:

- Low, zero, and negative pressure applications (<100 psi)

- Applications with quick valve closing and opening requirements

- Low flow rate applications (often the orifice diameter is limited to 25mm)

Indirect Action Solenoid Valves:

Indirect solenoid valves use the pressure difference across their valve ports to operate. The indirect solenoid valve essentially consists of a rubber membrane, or diaphragm, to separate its inlet and outlet ports.

Depending on the size of the valve, a minimum pressure differential between 0.1 to 0.5 bar is usually required between the two ports (in an NC valve) to lift the diaphragm and allow fluid flow from the inlet port over to the outlet port.

There's also an extra chamber above the diaphragm inside these valves, which acts as an amplifier, thus allowing them to control larger flow rates more effectively over direct-acting solenoid valves.

Due to being operated based on pressure difference, these valves regulate flow in only one direction and are more suited for high flow rate applications such as irrigation systems. It is recommended that you install a one way check valve to prevent backflow from damaging these types of valves.

Advantages of Indirect acting SVs:

- Higher flow rate capability compared to direct-acting

- Pressure assists valve operation, resulting in lower power consumption

- Economical for higher discharge/flow rates

Disadvantages of Indirect acting SVs:

- Cannot operate without a pressure difference

- It relies on the small holes within the diaphragm to operate. If they are blocked, the valve cannot operate

Applications:

Indirect-acting SVs are most suited for applications where

- Slow response or switching time is acceptable (Ex: water systems)

- Suitable for high-pressure applications (>100 psi)

Semidirect Action Solenoid Valves:

The semi-direct solenoid valve has the qualities of a direct operated valve and an indirectly operated valve, implying that it can work with no pressure while also being able to handle high flow rate applications.

This type of valve is designed similarly to an indirectly operated solenoid valve and contains an upper chamber, lower chamber, and a flexible membrane separating the two. The only opening in the membrane lets fluid fill up the upper chamber so that pressure can be equalized.

The main distinction between semi-direct and indirectly operated solenoid valves is that, in the former, the solenoid plunger is attached to and directly controls the diaphragm position. In contrast, indirect-operated valves use a pilot to control fluid in the upper chamber.

Working of Extra chamber/flow amplifier in Semi-direct and Indirect action SVs:

An indirect-acting SV has a diaphragm that separates the inlet port area and creates an upper chamber. This chamber is connected to the inlet port through a pressure equalizer hole. When the valve is idle or at rest, fluid passes from the inlet port into the upper chamber through the pressure equalizer hole to equalize pressure between both chambers (P1). When the (NC) SV Coil is electrically charged, fluid moves through a tiny orifice created by plunger movement. The fluid flows from the high-pressure upper chamber to the low-pressure (P2) outlet port due to pressure differential (P2 < P1). This flow results in two actions:

- Formation of a low-pressure area (P3, P3<P2) within the upper chamber above the diaphragm, and

- Contraction of diaphragm spring due to sudden flow from the upper chamber into the outlet port

When the diaphragm spring contracts, it opens up the flow from the inlet to the outlet ports. The flow rate is amplified because of the amplified pressure difference (P3 - P1) instead of the initial pressure difference (P2 - P1).

The difference between Indirect acting and Semi-direct acting SVs is that, in the Semi-direct valve, the plunger is directly connected to the diaphragm. Hence, when the coil is energized, the diaphragm lift provides an amplified pressure difference (P1 - P3) to cause the fluid to flow from the upper chamber to the outlet port. However, in indirect-acting SVs, an initial pressure difference (P1 - P2) is required for flow; therefore, these valves are also called pilot-acting or pilot-controlled SVs.

Controlling high-pressure flows using Semi-direct or Indirect Solenoid Valves:

By adjusting the power supply, you can also control how far the plunger is displaced. This displacement directly affects and controls the flow rate from the inlet to the outlet ports. Therefore, a high-pressure flow line can be efficiently managed by using a small solenoid valve--an advantage that direct-acting solenoid valves don't have.

Advantages of Semi-direct SVs:

- Perfect for a broad range of pressure applications, from zero (vacuum) to high-pressure (>100 psi)

- Lesser power consumption due to assisted lift due to pressure difference

- More powerful coils compared to indirect operated valves, resulting in higher service life and switching cycles

Disadvantages of Semi-direct SVs:

- Due to the small opening in the diaphragm, the working fluid should be free from debris to avoid valve clogging. Using a clean fluid or a y strainer reduces the risk of semi-direct valve clogging.

- High-flow and closed-loop systems

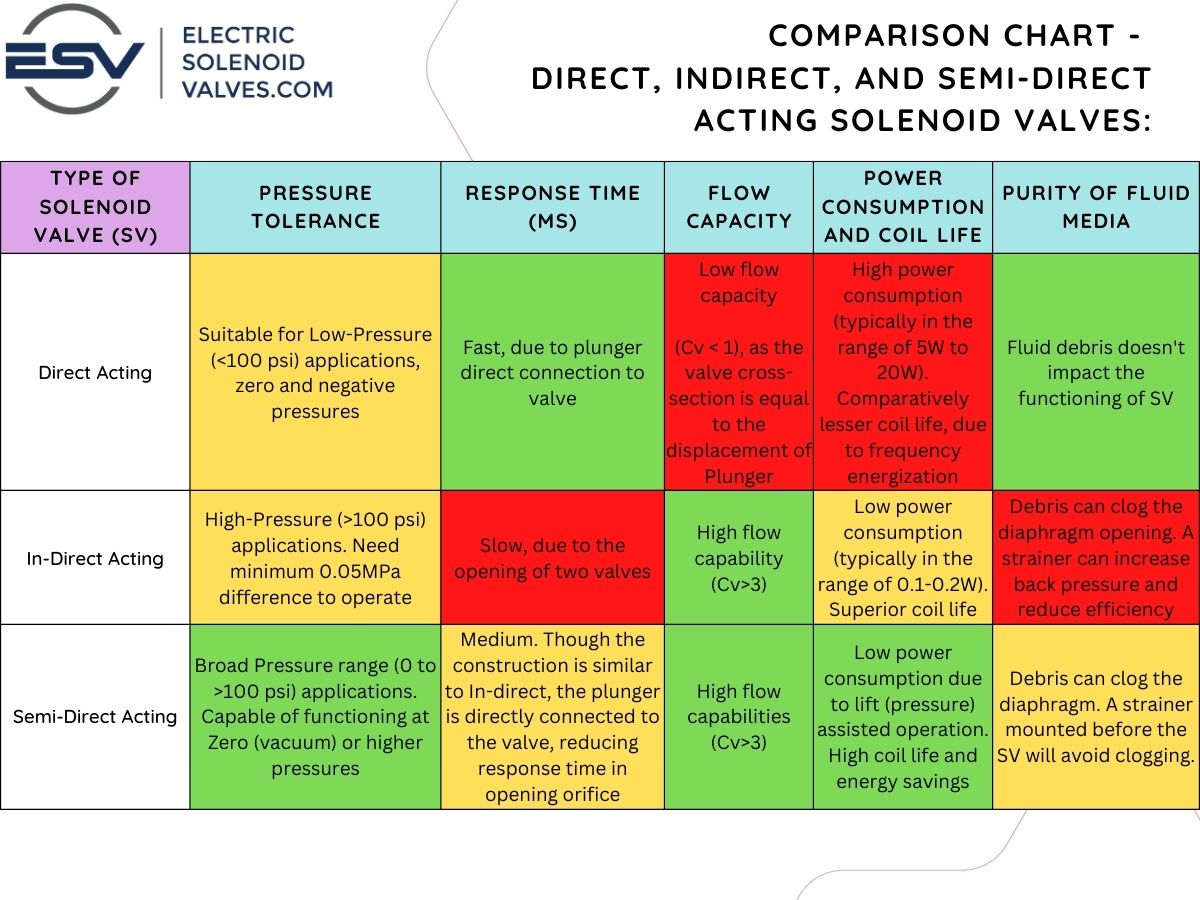

Comparison Chart - Direct, Indirect, and Semi-Direct Acting Solenoid Valves:

Summary:

Semi-direct solenoid valves are a type of valve that combines the best features of direct and indirect solenoid valves. They are suitable for a broad range of pressure applications, from zero (vacuum) to high pressure, making them ideal for high-flow and closed-loop systems. Semi-direct solenoid valves are also more powerful than indirect solenoid valves, making them a better choice for applications where reliability and long service life are important.

If you are interested in staying up-to-date on the latest smart automation products and technologies, check out our website or follow us on LinkedIn, where we regularly post news and reviews. We also offer a wide range of resources for gardeners of all experience levels, including tips, advice, and product recommendations.