Posted by Electronic Solenoid Valves on Feb 17th 2026

Water Control Valve Guide for Spring Startup, Prevent Leaks and Manage Flow

Spring startup puts every water control valve under stress. As temperatures shift and systems restart, weak seals, improper installation, and undersized valves begin to show as leaks, pressure spikes, and inconsistent flow. A properly selected water control valve stabilizes the system before those problems escalate.

This guide explains how water control valves function, which types perform best in spring conditions, and how to prevent seasonal failures before they start.

Why a Water Control Valve Fails During Spring Startup

When irrigation or plumbing systems restart after winter, risk increases. Pressure changes, trapped air, and mechanical stress strain the system.

- Thermal expansion and contraction loosen threaded connections

- Seals that sat dry begin to crack or leak

- Debris enters the lines during the first pressurization

- Sudden pressure surges create water hammer

Valves sit at the center of all these conditions. If the valve is undersized, improperly sealed, or incorrectly matched to the application, startup magnifies the problem.

A well-selected water control valve stabilizes pressure, isolates flow, and prevents damage during initial system pressurization.

What Is a Water Control Valve

A water control valve is a crucial mechanical device designed to regulate, direct, or completely stop the flow of water within a closed piping or distribution system. Its primary function is to provide precise management of water resources, ensuring the system operates efficiently, safely, and in accordance with specific process requirements. These valves are fundamentally the "traffic cops" of a water system, governing pressure, flow rate, and direction.

The operation of a water control valve can vary significantly depending on its design and application. It may be operated manually, requiring direct human intervention (such as turning a handwheel or lever), or it may operate automatically, responding to changes in system parameters like pressure, temperature, level, or time. Automatic valves are often actuated by hydraulic pressure, electric motors, or pneumatic systems, making them integral components of complex automation and SCADA (Supervisory Control and Data Acquisition) systems.

The versatility and necessity of water control valves make them indispensable across a wide spectrum of industrial, commercial, and municipal applications. They are critical for preventing leaks, managing surge pressures, conserving water, and maintaining system integrity. Key areas where water control valves are commonly utilized include:

- Irrigation Systems: Valves control the timed and measured release of water to fields, greenhouses, and landscape areas, optimizing water use and promoting crop health. This includes isolating zones, managing drip systems, and controlling center pivots.

- Plumbing and Water Distribution Systems (Municipal and Commercial): They are used to isolate sections for maintenance, reduce high pressure to safe levels (Pressure Reducing Valves - PRVs), prevent backflow contamination (Check Valves), and manage the overall flow from reservoirs to end-users.

- Cooling Water Loops and HVAC Systems: Valves regulate the flow of chilled or condenser water to maintain optimal thermal conditions in large buildings, industrial processes, and power plants, thereby ensuring efficient heat exchange.

- Car Wash and Washdown Stations: Robust and reliable valves are necessary to manage high-pressure water delivery and sequencing in automated wash processes, ensuring consistent operation and minimal waste.

- Light Industrial Process Lines: In manufacturing and processing facilities, valves control the flow of water used in mixing, rinsing, dilution, and cleaning processes, ensuring accurate and repeatable process control.

- Automation Systems with Timed Flow and Remote Control: Modern systems rely heavily on actuated (electric or hydraulic) control valves that are interfaced with programmable logic controllers (PLCs) to execute preset schedules, respond to real-time data, or allow remote system adjustments for maximum efficiency and water conservation.

In most systems, the valve performs one or more of these functions:

|

Function |

Purpose |

|

Isolation |

Fully stop the flow for maintenance or safety |

|

On Off Control |

Electrically or manually open and close the flow |

|

Flow Regulation |

Adjust the rate of flow |

|

Backflow Prevention |

Prevent reverse flow |

|

Automation |

Enable timed or sensor-based control |

The correct valve type depends on pressure, flow rate, automation needs, and installation constraints.

Common Types of Water Control Valves

Understanding valve type is critical during spring startup because each design behaves differently under pressure changes.

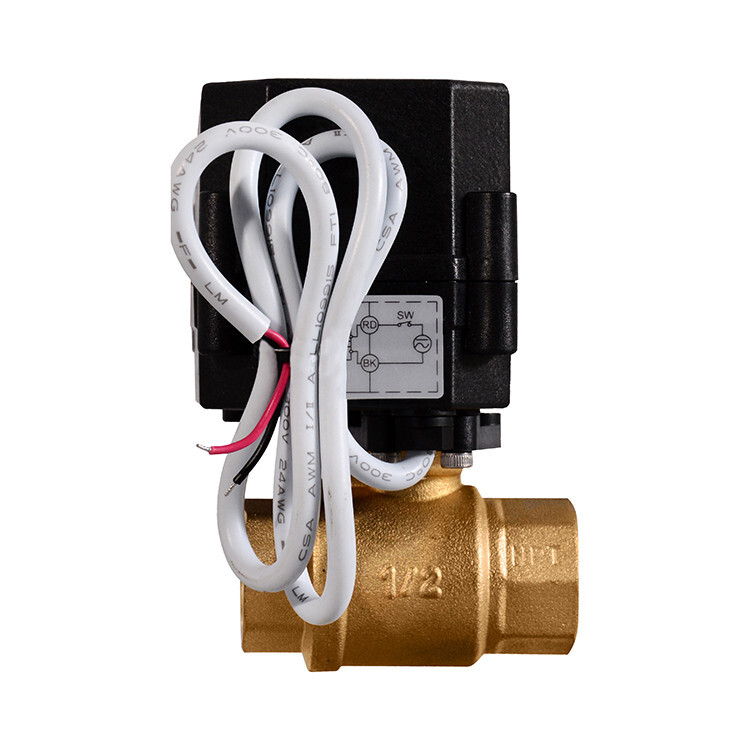

1. Solenoid Valves for Water

Solenoid valves are electromechanically operated devices integral to modern fluid control systems. Their function revolves around the use of an electromagnetic coil, which, when energized, creates a magnetic field. This magnetic force is then used to physically move a plunger or armature to either open or close the valve's orifice. This action automatically controls the flow of media—which can be water, air, oil, or gas—through the valve.

This automatic operation allows solenoid valves to be used for precise, remote control in applications ranging from simple on/off switching to complex proportional flow regulation.

|

Best for |

Advantages |

|

Irrigation automation |

Fast response |

|

Timed filling systems |

Compact design |

|

Remote on off control |

Easy integration with controllers |

|

Light industrial water control |

Ideal for automated spring restart |

For startup reliability, verify:

- Correct voltage

- Clean internal orifice

- Proper NPT thread sealing

2. Electric Ball Valves

Electric ball valves use a motorized actuator to rotate a ball 90 degrees. Electric ball valves are a type of quarter-turn valve that utilizes a motorized actuator to precisely control the flow of media by rotating a spherical ball 90 degrees (a quarter turn). This mechanism allows the valve to move quickly between a fully open position, where a bore through the center of the ball is aligned with the pipeline, and a fully closed position, where the solid side of the ball completely blocks the flow.

The electric actuator, which typically houses a motor, gearbox, and limit switches, is responsible for this rotational movement. When the valve is energized, the motor drives the rotation, providing significant torque to open or close the valve against pressure. This makes electric ball valves highly reliable for applications requiring positive shut-off and remote operation. They are commonly used for on/off service, but can also be used for throttling or flow modulation when equipped with a sophisticated modulating actuator. Their design offers excellent sealing capabilities and a relatively low pressure drop when fully open.

|

Best for |

Advantages |

|

Higher flow applications |

Full port design reduces pressure drop |

|

Systems needing slower controlled actuation |

Slower actuation reduces surge |

|

Water systems where water hammer is a concern |

More durable in higher debris conditions |

Spring startup tip: Motorized valves often tolerate sediment better than small orifice solenoids during first pressurization.

3. Manual Ball Valves

Manual ball valves serve as straightforward and reliable devices for on/off fluid control within a piping system. Their primary function is to provide simple shutoff control, allowing operators to quickly and completely stop or initiate the flow of water or other media. This is achieved by a rotating ball that has a bore through the center; when the bore is aligned with the flow path, the valve is open, and when the ball is rotated 90 degrees, the valve is closed, ensuring a tight seal and preventing leakage.

Spring startup tip: Check packing glands and threaded joints. Freezing and contraction can loosen seals.

4. Check Valves

Check valves, also commonly known as non-return valves (NRVs), are crucial components in many piping systems, serving the fundamental purpose of preventing reverse flow of the fluid (liquid or gas).

They are passive, two-port valves, meaning they operate automatically without the need for manual or external control.

|

Best for |

|

Pump discharge lines |

|

Irrigation systems |

|

Systems exposed to back siphoning |

Spring startup tip: Inspect for debris that may prevent proper seating.

How a Water Control Valve Prevents Leaks During Spring Startup

In most cases, leaks that occur during spring system startup are not due to valve defects. but rather issues related to installation and materials. Addressing these common problems is key to a leak-free season.

Common Causes and Solutions for Spring Leaks

|

Cause |

Symptoms/Description |

Solution |

|

1. Improper Thread Sealing |

Occurs with NPT threads, often due to overtightening, cross-threading, or mixing NPT/BSP thread types. Requires correct application of PTFE tape or approved thread sealant. |

Confirm NPT thread compatibility, use the proper sealant, and apply the correct torque. |

|

2. Undersized Valve Selection |

High-velocity flow and pressure spikes are created, leading to vibration, premature seal wear, and water hammer. Increased stress is placed on the system during startup. |

Verify the required flow rate and match the valve's Cv rating to the application. Avoid oversizing, which compromises control stability. |

|

3. Water Hammer |

Rapid opening or closing of valves during startup causes damaging pressure spikes. Electric ball valves inherently reduce this risk due to their gradual actuation. |

Consider valves with slower actuation (e.g., electric ball valves) or install surge dampening/pressure relief devices. Ensure pipe supports are secure. |

|

4. Seal Degradation |

Rubber and elastomer seals (such as NBR, EPDM, Viton) can dry out or shrink over cold winter months. |

Confirm the seal material's compatibility with water temperature, chemical additives, and outdoor UV exposure. Replacing a seal is a cost-effective measure to prevent body damage from leakage. |

When Automation Makes Sense in Spring Systems

Manual operation works for simple systems. However, during spring startup often exposes inefficiencies in manual control.

Automation improves:

- Irrigation timing

- Water conservation

- Leak prevention

- Remote shutoff capability

A solenoid valve or electric ball valve enables integration with:

- Irrigation controllers

- Timers

- Float switches

- Pressure switches

- Building automation systems

For residential and light commercial applications, solenoid valves remain the most cost effective automation solution. For higher flow or surge sensitive systems, electric ball valves offer better mechanical stability.

Material Selection for Wet Environments

Spring also brings increased outdoor exposure.

When choosing a water control valve, evaluate body material:

|

Material |

Ideal Use |

|

Brass |

Indoor plumbing, moderate exposure |

|

Stainless Steel |

Corrosive or outdoor exposure |

|

Plastic |

Irrigation and light duty outdoor |

If installed outdoors:

- Verify UV resistance

- Confirm IP rating on coils

- Protect wiring connections

Seasonal Startup Checklist for Water Control Valves

Use this checklist before fully pressurizing your system:

Mechanical

- Inspect threaded joints

- Check valve body for cracks

- Confirm correct thread type

Electrical

- Verify voltage supply

- Check coil continuity

- Inspect wiring insulation

Flow

- Flush lines before final installation

- Gradually pressurize

- Observe for leaks

Operation

- Cycle valve multiple times

- Confirm full open and full close

- Monitor for vibration or noise

How to Choose the Right Water Control Valve for Spring Systems

Before ordering, confirm:

- Flow rate requirement

- Pressure rating

- Voltage availability

- Installation environment

- Automation needs

- Seal material compatibility

If unsure, start with the application type:

|

Application |

Recommended Valve |

|

Solenoid valve |

|

|

Higher flow washdown |

Electric ball valve |

|

Simple shutoff |

Manual ball valve |

|

Pump discharge |

Check valve |

Avoid the common mistake of choosing based on size alone. Performance depends on flow characteristics, not just port diameter.

Final Thoughts

Spring startup is when water systems reveal weaknesses. Leaks, surges, and inconsistent flow are usually selection or installation issues, not random failures.

A properly selected water control valve stabilizes your system before problems develop. Whether you are automating irrigation, managing plumbing flow, or restarting a cooling loop, the valve is the control point that determines performance.

A reliable startup begins with the correct valve choice, proper sealing, and structured commissioning.

Ready to prepare your system for spring startup? Browse water control valves:

If you need help selecting the correct valve, contact our team for application support.