Posted by Electric Solenoid Valves on Nov 11th 2025

The Benefits of a Motorized Ball Valve and How It Operates

Motorized ball valves pair a quarter-turn ball valve with an electric actuator. They deliver full-port flow, low pressure drop, and a gentle open and close that reduces water hammer. Compared to many solenoid valves, they handle larger sizes and dirty media more reliably, and they typically draw power only while moving. See ESV’s category for in-stock options in brass and stainless steel.

How a motorized ball valve works

Main components

- Valve body and ball: brass or stainless options on ESV. PTFE seats for low friction and tight shutoff. (its also available in UPVC)

- Actuator: geared motor drives 90-degree rotation, internal limit switches stop power at the end of travel.

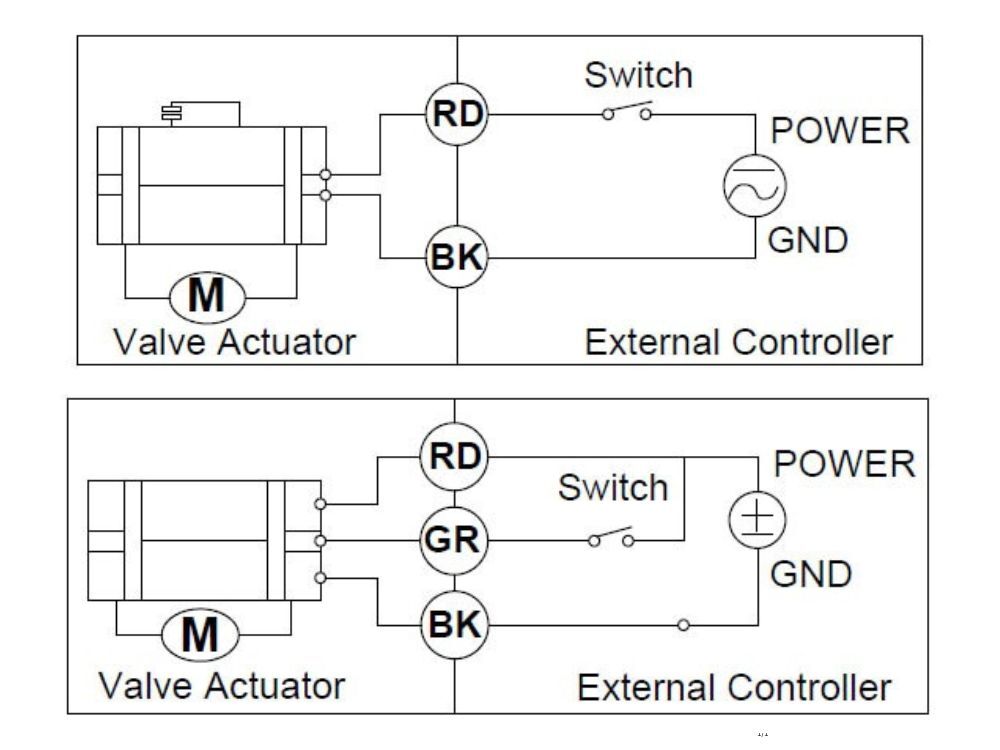

- Return method:

- 2-wire auto return: actuator charges an internal capacitor during opening, on power loss it drives the valve back to the normal position.

- 3-wire control: direction controlled by a switched lead, stays in the last position until commanded. IP67 on XR33 models noted on ESV.

Typical run time

- About 4 to 5 seconds per 90 degrees, which helps avoid water hammer. (4 to 5 is for ½” to 1”. 1-½” actuates for 12 seconds, while 2” is 15 seconds)

https://www.electricsolenoidvalves.com/1-1-2-stainless-electric-ball-valve-2-wire-auto-return/

https://www.electricsolenoidvalves.com/2-stainless-electric-ball-valve-2-wire-auto-return/

Advantages vs solenoid valves

|

Use case |

Motorized ball valve |

Solenoid valve |

|

Flow and pressure drop |

Full-port, very low ΔP |

Higher ΔP due to internal geometry |

|

Water hammer |

Slow actuation helps avoid spikes |

Fast snap action can cause the hammer |

|

Power usage |

Draws mainly while moving |

Many types are drawn to hold a state |

|

Size range |

Readily available up to 1 in on ESV, larger common in the industry (our electric ball valves are available up to 2”) |

Most economical at small sizes |

|

Dirty media |

Ball and seats tolerate particulates better |

Small orifices can foul |

Check this link for our selection of electric ball valves.

Why buyers pick them: high flow, gentle operation, simple on off or basic control, minimal heat buildup in panels. ESV’s category description highlights the anti-water-hammer behavior and higher flow versus solenoid valves.

Electrical options on ESV

- 2-wire auto return, XR22 family:

- 9 to 24 VAC/DC auto detect, or 110 to 230 VAC.

- Charges an internal capacitor while opening, and returns the valve on power loss.

- 3-wire control, XR33 family:

- 9 to 24 VAC/DC or 110 to 230 VAC.

- Red to hot, black to neutral, green switched to hot for open or close. NEMA 4 and IP67 listed on ESV 3-wire pages.

- Open and close time: 4 to 5 seconds, typical

- Ingress protection: IP ratings explained with examples on ESV, including IP67 callouts on motorized valves.

Quick spec reference

|

Electricsolenoidvalves Product |

Size, body |

Seats, seals |

Electrical |

Run time |

Return or hold |

Notes |

|

1/2 in Brass, 2-wire auto return |

1/2 in brass, full port |

PTFE seat, FKM/Viton seal |

XR22, 9-24 VAC/DC or 110-230 VAC |

~4-5 s |

Auto return on power loss |

Full flow, low power to hold. |

|

1 in Brass, 2-wire auto return |

1 in brass, full port |

PTFE seat, FKM/Viton seal |

XR22, 9-24 VAC/DC or 110-230 VAC |

~4-5 s |

Auto return |

The top position indicator is shown. |

|

1/2 in Stainless, 2-wire auto return |

1/2 in 304 SS, full port |

PTFE seat, FKM/Viton seal |

XR22, 9-24 VAC/DC or 110-230 VAC |

~4-5 s |

Auto return |

Full flow without restriction. |

|

1/2 in Brass, 3-wire |

1/2 in brass |

PTFE seat, FKM/Viton seal |

XR33, 9-24 VAC/DC or 110-230 VAC |

~4-5 s |

Holds the last state |

NEMA 4, IP67 on page. |

|

1/2 in Stainless, 3-wire |

1/2 in SS |

PTFE seat, FKM/Viton seal |

XR33, wiring: red hot, black neutral, green switched hot |

~4-5 s |

Holds the last state |

Bi-directional flow. |

Selection steps

- Confirm media and temperature

Brass for general water and glycol, stainless for corrosive or food areas. ElectricSolenoidValves covers the pros and cons of each material in a dedicated guide. - Pick return behavior

- 2-wire auto return for a safe state on power loss. XR22 does this via an internal capacitor.

- 3-wire hold when the last position is acceptable, and you need simple directional control with feedback. XR33 details and wiring on ESV.

- Match voltage and control

9-24 VAC/DC or 110-230 VAC, confirm panel power

- Size for flow

Choose full-port in your line size for minimal pressure drop. Full-flow claims are noted on ESV product pages. - Check environment

If exposed to spray or weather, look for IP67 on 3-wire options, and follow ESV’s IP explainer for what each rating means. (The XR22 & XR33 are both rated IP67)

Wiring basics

- 2-wire auto return (XR22): apply power to open, internal capacitor charges, on power loss the valve returns to normal. Allow at least about 60 seconds of power to maintain return capacity. See the XR wiring PDF. (Our electric ball valves are normally closed by default, but can be converted to normally open, so it would be better to say “apply power to change the valve position. On power loss, the capacitor drives the valve back to its default position.”)

- 3-wire control (XR33): red to hot, black to neutral, green to hot through a switch or relay to drive movement. NEMA 4, IP67 noted on the brass 3-wire page. (The XR22 & XR33 are both rated IP67)

Check these link for more details

- Troubleshooting: ESV’s guide covers low-voltage symptoms and basic checks.

Installation checklist

Before installation

- Flush lines, keep PTFE tape one to two threads back.

- Verify clearance above the actuator.

- Confirm wiring path and power supply.

During installation

- Support piping, avoid side load on threads.

- Tighten to spec, then jog open and close before pressurizing.

Commissioning

- Cycle a few times, check for leaks, and listen for abnormal noise.

- Confirm feedback or end limit status at the controller.

When to choose fail closed, fail open, or hold the last state

- Auto return closed: default for most supply lines or emergency shutoff. XR22 does this automatically on power loss.

- Hold last state (3-wire): loops and bypasses where a loss of power should not change the position.

Applications

- Irrigation zones and fertigation, gentle open prevents hammer.

- HVAC water and glycol loops that need low pressure drop.

- Car wash chemical control and reclaim.

- Simple mixing or diverting with 3-way electric ball valves.

Ready to spec an electric ball valve, choose 2-wire auto return for a safe default on power loss or 3-wire control when you need the valve to hold position. Shop full-port brass and stainless options with IP67 models and sizes up to 2 in. If you want help matching voltage, fail behavior, or run time, contact us or shop for Motorized Ball Valves.

FAQs

Q: Do these valves cause water hammer?

The slow 4 to 5 second travel helps avoid water hammer.

Q: Can they return to a safe position on power loss?

Yes, XR22 2-wire auto return uses an internal capacitor to drive closed when power is cut.

Q: Are there outdoor-rated options?

Yes, 3-wire units on ESV note NEMA 4 and IP67. Match the IP rating to your environment.

Q: Do they allow full flow?

ESV product pages specify full flow without restriction. Use full-port sizes for the lowest pressure drop.